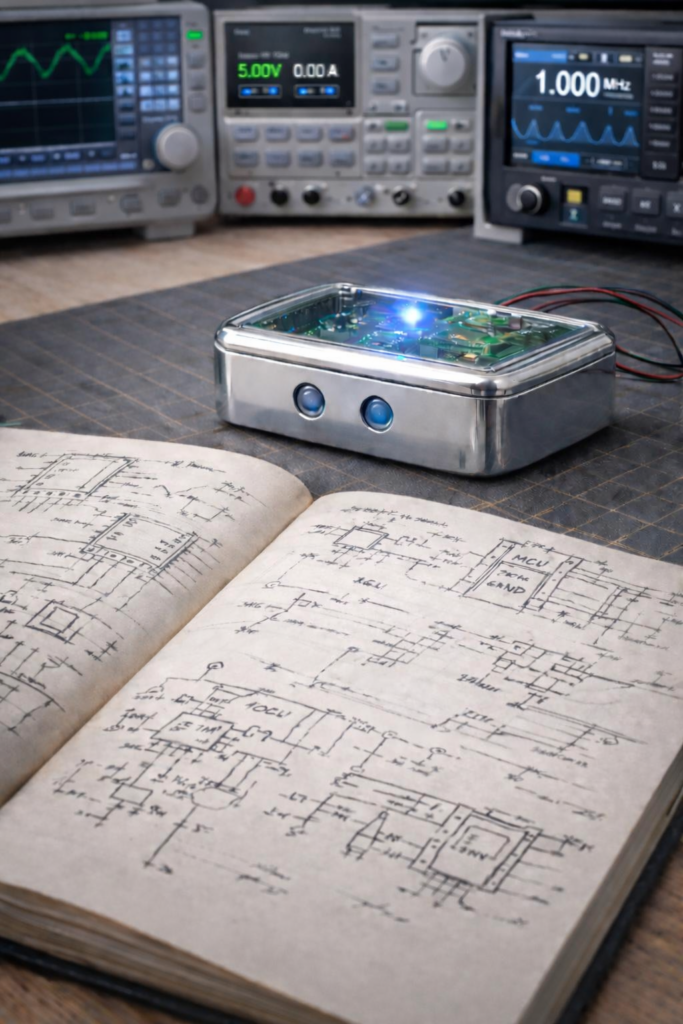

You bring the idea. We build the device

From concept to working prototype – Electronics designed, built, debugged and tested for you by senior engineers with over 40 years of hands-on experience in research, development and commercial innovation.

Practical electronics development and engineering for funded startups and retired innovators.

If you’re serious about building a real product – not just concepts on paper – you’re in the right place.

Don’t let your idea stall

Most great ideas fail because they are never started seriously – they stall between CONCEPT and REALITY.

In electronics, most ideas die somewhere between the sketch and the circuit board. Poor design decisions, unreliable prototypes, and a lack of experienced engineering judgement mean many ideas never make it past the early stages.

Geniusin exists to bridge that gap.

Who we work with

Startups with Funding

You have a commercial idea and the funding to explore it. You need a prototype that shows investors, partners and early customers you aren’t just theorising.

We can help and design the electronics, firmware and hardware that proof-out your concept.

Retired and Early-Retired Innovators

You’ve spent a career knowing exactly what tool, device or system should exist – but never had the time to make it real. Now you do.

We can help you turn decades of your insight into a tangible electronic product.

Core services

These two services work best together, but they don’t have to. Design validation provides clarity — a grounded understanding of what’s viable and what isn’t — while Idea → Prototype creates momentum by turning that clarity into something tangible. Both are designed to reduce risk, increase confidence, and help good ideas survive first contact with reality.

Why work with us

When you work with us, you work directly with Paul — backed by a lifetime of engineering experience.

Paul is our Senior Electronics Specialist and founder of Geniusin. He has spent more than 40 years designing electronics, leading R&D teams, and helping ideas become reliable, working systems. His experience spans defence, retail intelligence, and consumer devices, and includes founding and leading technology businesses as well as hands-on engineering work.

He previously held the role of Managing and Technical Director at Synovate Retail Performance, where he led the development and large-scale deployment of electronic systems across multiple countries. During this time, he was recognised as one of the top 0.5% of UK business leaders by Who’s Who of Britain’s Business Elite.

Today, Paul focuses on what he has always valued most: working directly with founders and innovators to design, build, debug, and validate electronic prototypes. He is a senior electronics specialist, a long-standing member of the IEEE, and someone who cares deeply about building things properly.

Our portfolio

Much of our work is covered by non-disclosure agreements and cannot be shared publicly. This is typical of the projects we’re involved in — particularly early-stage ideas, commercially sensitive products, and defence-related work.

The examples shown here illustrate the type of problems we’re often asked to solve and the outcomes achieved, rather than the full breadth of our experience.

If it’s helpful, we’re always happy to talk more openly during a discovery call, where context can be shared appropriately and confidentiality arrangements can be put in place.

Contact us

If you have an idea you’re considering, or an existing product that needs a second look, we’re happy to have an initial conversation. Often, a short discussion is enough to clarify feasibility, surface potential risks, and identify sensible next steps. There’s no obligation — just practical engineering insight to help you make an informed decision.